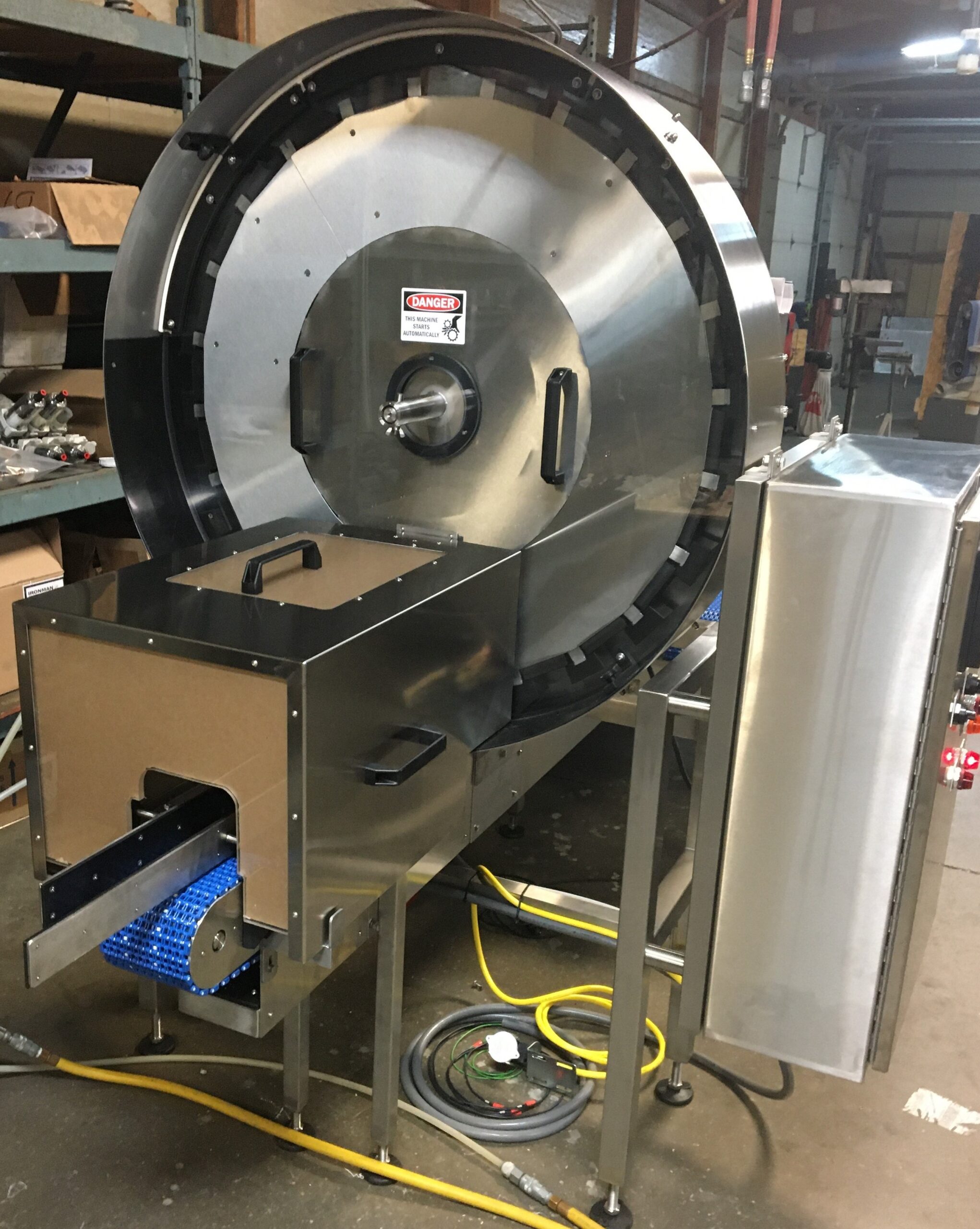

UNUSED McBrady Engineering Orbit Model 100 deionized air rinser bottle cleaner with 4-belt unscrambler

This equipment was designed and built for a project that was cancelled after the FAT was completed. It has never run in production. It is in original factory crates.

The model 100 ORBIT bottle cleaner was designed and built to invert and rinse glass jars and crocks with deionized air at speeds of up to 50 containers per minute.

Two (2) sets of container change parts included.

Containers are rinsed while inverted by stationary air nozzles.

A semi-circular dustpan is located directly below the inverted containers. The dustpan connects directly to the Donaldson Torit model 64 cabinet dust collector through an exhaust port on the side of the cleaner.

Machine includes the following features:

– 48” diameter drum

– Infeed and discharge photo units

– Discharge bolt down guard

– Allen Bradley electrical components

– Allen Bradley PowerFlex 525 VFD with ethernet connectivity

– Easy Changeover (Requires only the interchanging of parts, no adjustments)

– Minimal maintenance required

– Air ionizing kit

– Air pressure loss switch

– Included stainless steel package upgrade includes: washdown motors, reducers, stainless steel bearings, chains, leveling feet, and electrical enclosure.

– Vacuum Pressure Loss Switch

– Orbit 100 bottle cleaner / 4-belt unscrambler Dimensional DRAWINGS

– Specific containers that this equipment was designed to run.

– McBrady Engineering Orbit bottle cleaner brochure

– Factory Acceptance Test (FAT) Video